Product center

Contact us

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

The die-casting process is a process that uses three major elements: machine, mold and alloy to unify pressure, speed and time.Used for metal thermal processing, the existence of pressure is the main feature of the die-casting process that distinguishes it from other casting methods. Pressure casting is a special casting method that develops rapidly in modern metal processing technology and requires little cutting.It is a process in which molten metal fills the casting mold under high pressure and high speed, and crystallizes and solidifies under high pressure to form a casting. This method is used to produce products with high production efficiency, simple process, high casting tolerance level, good surface roughness and mechanical strength. Large, it can save a lot of mechanical processing procedures and equipment, save raw materials and other advantages, so it has become an important part of the foundry industry.

The die-casting process is a process that uses three major elements: machine, mold and alloy to unify pressure, speed and time.Used for metal thermal processing, the existence of pressure is the main feature of the die-casting process that distinguishes it from other casting methods. Pressure casting is a special casting method that develops rapidly in modern metal processing technology and requires little cutting.It is a process in which molten metal fills the casting mold under high pressure and high speed, and crystallizes and solidifies under high pressure to form a casting. This method is used to produce products with high production efficiency, simple process, high casting tolerance level, good surface roughness and mechanical strength. Large, it can save a lot of mechanical processing procedures and equipment, save raw materials and other advantages, so it has become an important part of the foundry industry.

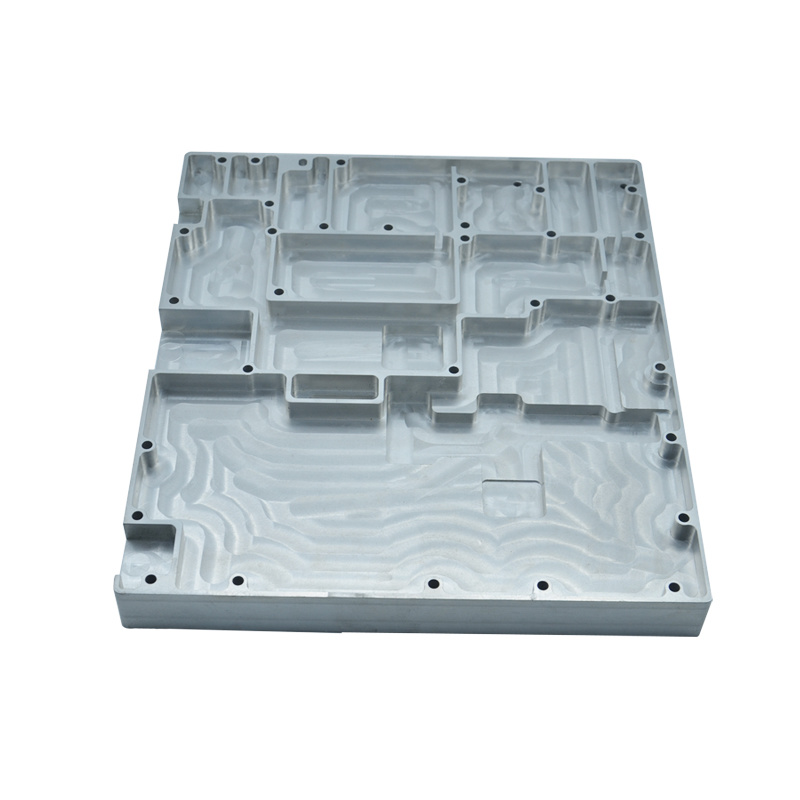

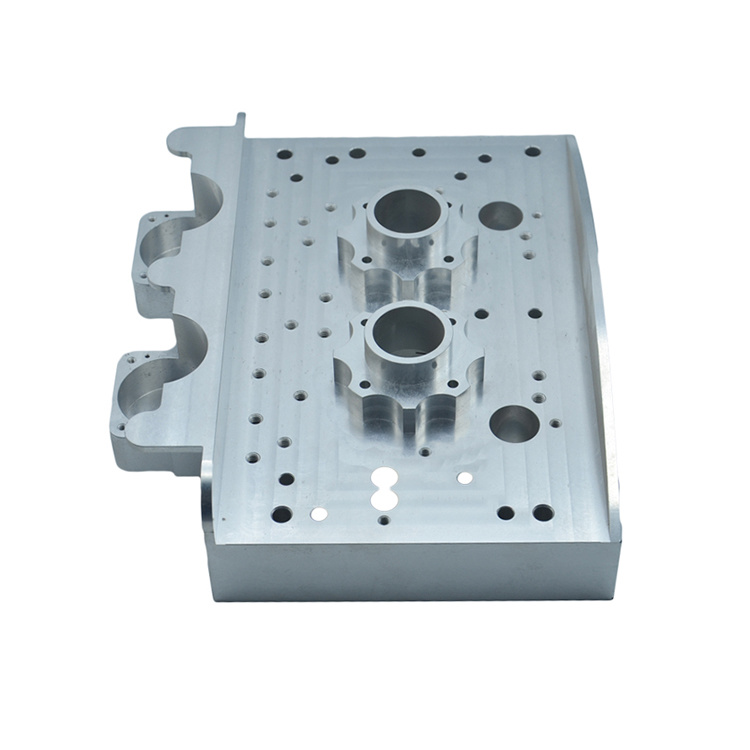

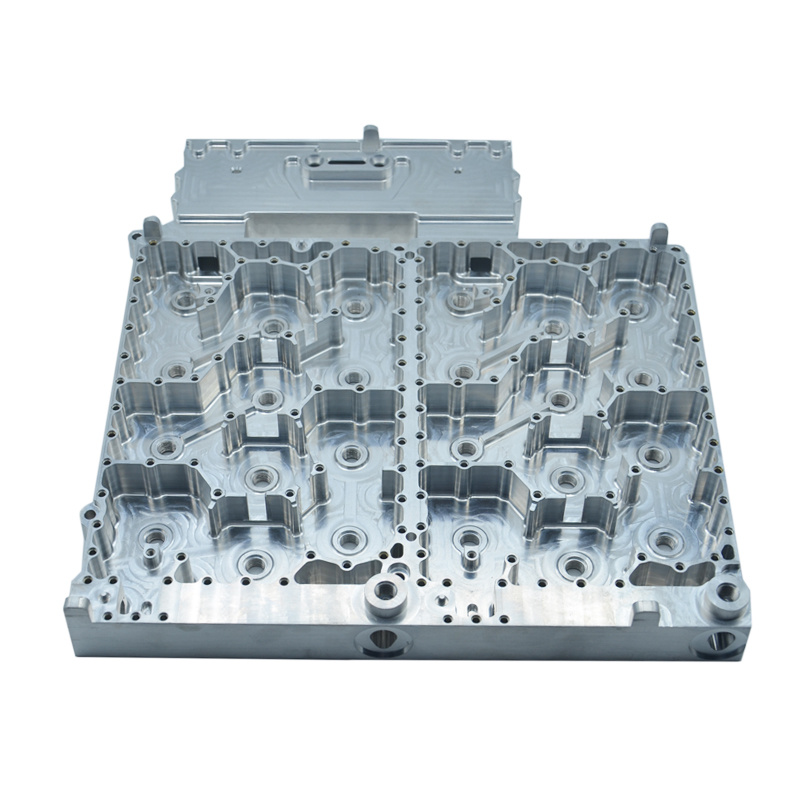

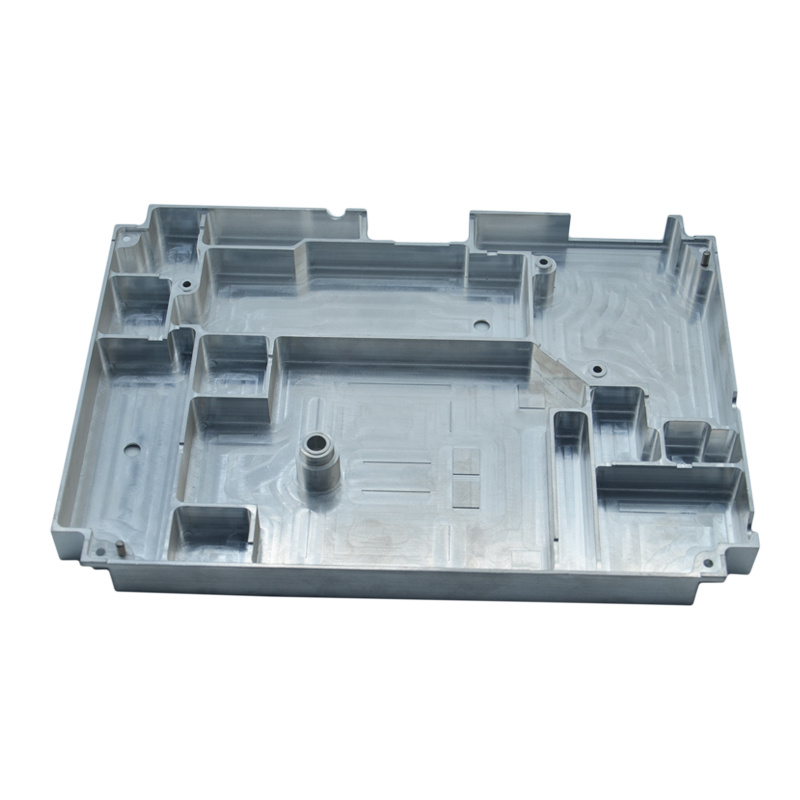

AD12 die casting cnc machining

The die-casting process is a process that uses three major elements: machine, mold and alloy to unify pressure, speed and time.Used for metal thermal processing, the existence of pressure is the main feature of the die-casting process that distinguishes it from other casting methods. Pressure casting is a special casting method that develops rapidly in modern metal processing technology and requires little cutting.It is a process in which molten metal fills the casting mold under high pressure and high speed, and crystallizes and solidifies under high pressure to form a casting. This method is used to produce products with high production efficiency, simple process, high casting tolerance level, good surface roughness and mechanical strength. Large, it can save a lot of mechanical processing procedures and equipment, save raw materials and other advantages, so it has become an important part of the foundry industry.

The die-casting process is a process that uses three major elements: machine, mold and alloy to unify pressure, speed and time.Used for metal thermal processing, the existence of pressure is the main feature of the die-casting process that distinguishes it from other casting methods. Pressure casting is a special casting method that develops rapidly in modern metal processing technology and requires little cutting.It is a process in which molten metal fills the casting mold under high pressure and high speed, and crystallizes and solidifies under high pressure to form a casting. This method is used to produce products with high production efficiency, simple process, high casting tolerance level, good surface roughness and mechanical strength. Large, it can save a lot of mechanical processing procedures and equipment, save raw materials and other advantages, so it has become an important part of the foundry industry.

The die-casting process is a process that uses three major elements: machine, mold and alloy to unify pressure, speed and time.Used for metal thermal processing, the existence of pressure is the main feature of the die-casting process that distinguishes it from other casting methods. Pressure casting is a special casting method that develops rapidly in modern metal processing technology and requires little cutting.It is a process in which molten metal fills the casting mold under high pressure and high speed, and crystallizes and solidifies under high pressure to form a casting. This method is used to produce products with high production efficiency, simple process, high casting tolerance level, good surface roughness and mechanical strength. Large, it can save a lot of mechanical processing procedures and equipment, save raw materials and other advantages, so it has become an important part of the foundry industry.

The die-casting process is a process that uses three major elements: machine, mold and alloy to unify pressure, speed and time.Used for metal thermal processing, the existence of pressure is the main feature of the die-casting process that distinguishes it from other casting methods. Pressure casting is a special casting method that develops rapidly in modern metal processing technology and requires little cutting.It is a process in which molten metal fills the casting mold under high pressure and high speed, and crystallizes and solidifies under high pressure to form a casting. This method is used to produce products with high production efficiency, simple process, high casting tolerance level, good surface roughness and mechanical strength. Large, it can save a lot of mechanical processing procedures and equipment, save raw materials and other advantages, so it has become an important part of the foundry industry.

The die-casting process is a process that uses three major elements: machine, mold and alloy to unify pressure, speed and time.Used for metal thermal processing, the existence of pressure is the main feature of the die-casting process that distinguishes it from other casting methods. Pressure casting is a special casting method that develops rapidly in modern metal processing technology and requires little cutting.It is a process in which molten metal fills the casting mold under high pressure and high speed, and crystallizes and solidifies under high pressure to form a casting. This method is used to produce products with high production efficiency, simple process, high casting tolerance level, good surface roughness and mechanical strength. Large, it can save a lot of mechanical processing procedures and equipment, save raw materials and other advantages, so it has become an important part of the foundry industry.

The die-casting process is a process that uses three major elements: machine, mold and alloy to unify pressure, speed and time.Used for metal thermal processing, the existence of pressure is the main feature of the die-casting process that distinguishes it from other casting methods. Pressure casting is a special casting method that develops rapidly in modern metal processing technology and requires little cutting.It is a process in which molten metal fills the casting mold under high pressure and high speed, and crystallizes and solidifies under high pressure to form a casting. This method is used to produce products with high production efficiency, simple process, high casting tolerance level, good surface roughness and mechanical strength. Large, it can save a lot of mechanical processing procedures and equipment, save raw materials and other advantages, so it has become an important part of the foundry industry.